How Mines Can Use Sustainable Water Solutions to Drive a Cleaner Future

Mining is the driving engine of many economies. But, mining is also a resource-intensive industry. It’s particularly reliant on water right across its value chain, needing litres upon litres for processes like mineral processing and cooling machinery. Historically, this reliance has led to groundwater pollution, freshwater depletion, and contamination – all exacerbating water scarcity in water-stressed areas.

This impact will only intensify in the years to come. As the world turns more urgently to clean energy solutions, mining will be responsible for extracting the metals and rare-earth minerals needed to build solar panels and electric vehicles. To ensure long-term business operations and environmental sustainability, more mines are putting responsible water management front and centre.

Chelsea Water can help mines transform their impact through innovative water treatment and supply solutions.

The role of mining in climate change and clean energy

With fossil fuel emissions accelerating climate change – as well as affecting global fresh and groundwater supply – the transition to clean energy is all the more urgent. Mining plays a critical and environmentally interconnected role in this transition.

A joint 2025 report from the World Economic Forum and Oliver Wyman shows:

Demand for critical rare-earth minerals used in clean energy is projected to increase four to six times by 2040.

A typical electric car requires six times more mineral inputs than a fuel-powered vehicle, and an onshore wind plant needs nine times more mineral resources than a gas-fired plant.

Extraction of metals and minerals used in clean energy occurs in specific areas. For example, 75% of the world’s cobalt is from the Democratic Republic of the Congo and 70% of rare earth elements are from China.

That’s why, as an industry, mining has the power to enact positive change, especially when it comes to water.

The close relationship between mining and water

Water is used in almost every aspect of mining, from dust suppression and cooling machinery to being an essential ingredient in chemical processes.

Mines use water to separate material from rocks in centrifugal processes, to wash equipment, and to de-water mines (when mines go below the water table, the water needs to be pumped out). And because many mines are in remote areas, safe drinking water is also needed to support towns and communities that have developed around the industry.

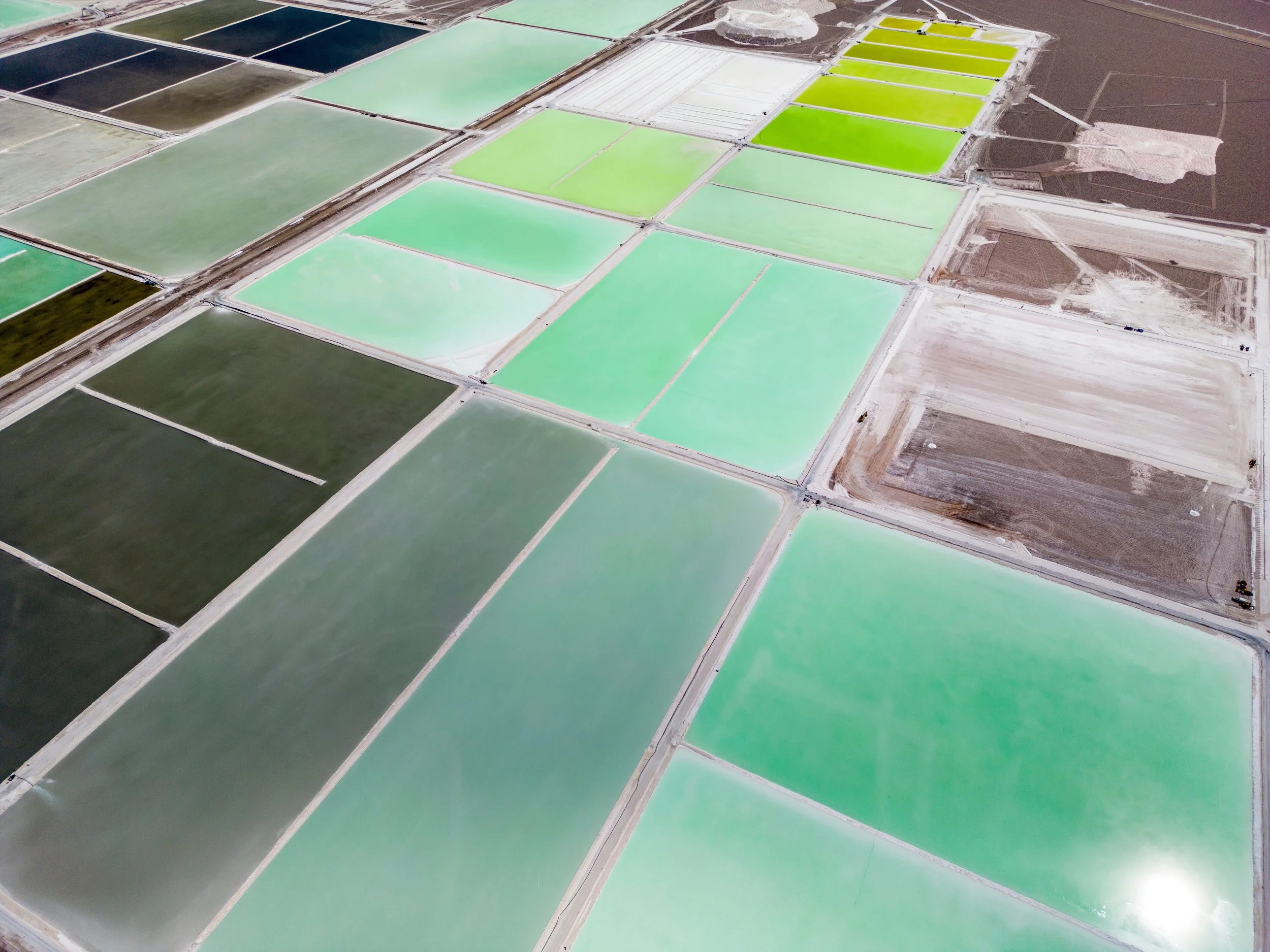

Water is also used intensively in extracting minerals like lithium, also known as ‘white gold’. For example, over half the world’s lithium supply is found in South America’s ‘lithium triangle’, which includes parts of Chile, Argentina, and Bolivia. Mines pump brine from the region’s salt flats into large pools on the surface of these flats. The water evaporates, leaving behind lithium carbonate, which is used in manufacturing lithium-ion batteries, an essential component in renewable energy.

Lithium fields in the Atacama Desert in Chile, where lithium is mined for batteries used in clean-energy solutions.

Mining’s impact on water and water sources

Due to its extensive and intensive use of water, mining has a significant impact on this precious natural resource. For example:

Studies show that one tonne of lithium extraction uses about 2 million litres of water.

According to data from the U.S. Geological Survey (USGS) and WRI’s Aqueduct tool, 16% of the world’s land-based critical mineral mines, deposits, and districts are in areas with high or extremely high levels of water stress.

The industry uses up to 4.5% of national water demand in areas with heavy mining activity. This has a major impact on freshwater resources within local areas, especially those with high levels of water scarcity.

Acid mine drainage is a severe environmental issue in South Africa, which has the world’s largest reserves of platinum and manganese. Acid mine drainage is caused by the oxidation of sulphide during mining, producing acidic water that pollutes water sources with toxic heavy metals.

The drowned village of Geamana in Romania, where the industrial wastewater from a nearby copper mine was pumped into a previously fertile valley.

How mines can reduce their water impact

Mining can make its water footprint much smaller by adopting efficient technologies and sustainable practices. For example, recycling water by treating wastewater at scale, adopting more water-efficient processes, and working closely with communities all go a long way in conserving this resource and protecting the environment.

According to The World Economic Forum, key areas to focus on include:

Adopting less water-intensive processes

Traditional water-heavy processes can be replaced with more efficient alternatives. For example, switching from lithium evaporation to direct lithium extraction, using powder for dust control, and upgrading to air-cooling processes significantly reduce water usage.

Switching to sustainable water practices

Using alternative sources like treated wastewater or harvesting rainwater decreases reliance on freshwater systems. Implementing closed-loop water recycling systems and developing solutions to store water when there’s a surplus helps ease pressure on local ecosystems and water users.

Wastewater from copper mines are usually treated to remove pollutants and heavy metals.

Closely collaborating with communities

Partnerships with local communities who live near mines are key to sustainable water management. These are the people most affected by mining operations. With joint planning and transparent water use reporting, mines can foster trust, reduce conflict, and promote shared water stewardship.

For example, at a gold mine in the Democratic Republic of the Congo, Barrick Gold worked with a local community development committee to invest in a water distribution project to pump and purify water to a network of 40 water fountains in a nearby city. And, Anglo American has partnered with Peruvian communities for over a decade to improve the quality and availability of water for more than 6,000 local farmers.

How innovative water treatment and supply technologies benefit mining

Without proper treatment, water from mining processes can damage ecosystems, contaminate drinking supplies, and threaten people’s health.

Chelsea Water’s Custom Containerised solution creates a water treatment plant fit to purpose. The modular design allows the plant to be scaled as needed, quickly installed (in weeks instead of months) or dismantled and moved to a new location if needed.

Benefits of using this water treatment technology include:

Quick response capability: Chelsea Water’s mobile trailer units are built for rapid deployment, ideal for remote and underserved areas. These systems can begin treating water within hours of arrival on site.

Made for off-grid: Fully self-contained and with diesel generator and solar power options, the trailer is ideal for areas with limited infrastructure.

Durable and sustainable: This mobile unit also provides a fast and reliable solution that enables access to clean drinking water for mining staff and communities living near mining areas.

Helping mining make a positive impact

Chelsea Water is here to help mines find the best-fit solution for water treatment and purification needs at scale. Contact us today to explore custom water treatment and purification systems for mining operations, including those in remote and arid regions.

Together, we can help make mining more sustainable. With the right water treatment solutions in place, mining can drive economies towards future success, while creating a world powered by cleaner energy.